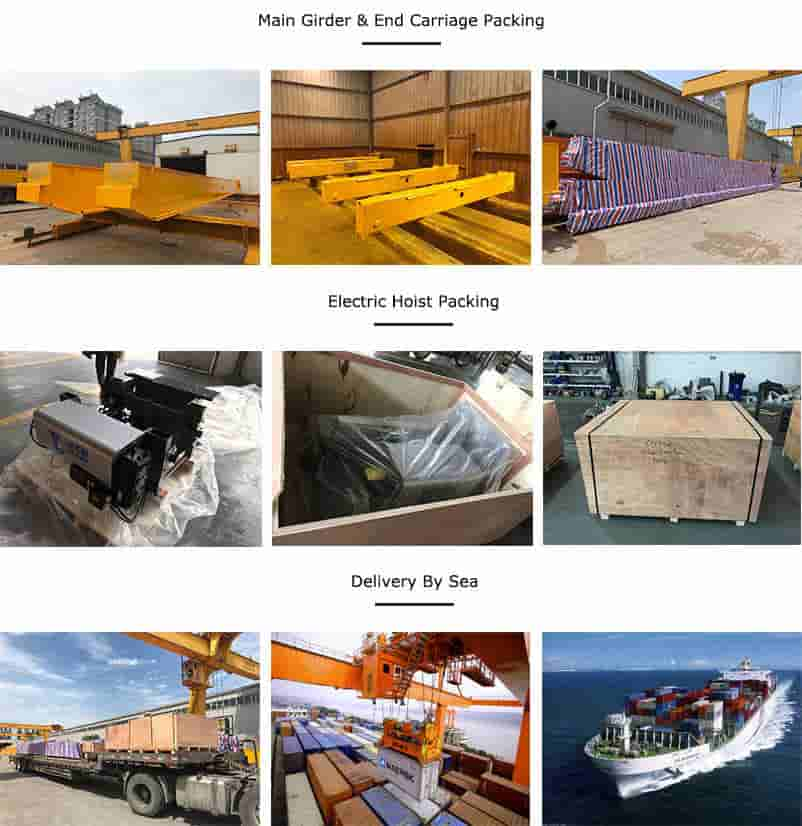

We have completed 1 bridge crane installation project in Pakistan, which includes 1 set of 10 ton overhead crane and 1 set of 20 ton overhead crane, all models are QZ double girder Grab Bucket Overhead Crane. All crane components are shipped from Qingdao Port in China to Qasim Port in Pakistan by sea after they are produced in the crane factory in China.

|

Lifting capacity |

t |

15 |

20 |

|

|

Lifting height |

m |

11.5 |

11.5 |

|

|

Span |

m |

15.75 |

15.75 |

|

|

Speed |

Trolley traveling |

m/min |

39.7 |

39.7 |

|

Crane traveling |

71 |

71 |

||

|

Lifting |

7.9 |

7.2 |

||

|

Working class |

/ |

ISO M5 |

ISO M5 |

|

|

Power supply |

V/Hz |

380v, 3phase, 50hz |

380v, 3phase, 50hz |

|

|

Trolley traveling power |

KW |

4 |

4 |

|

|

Crane traveling power |

2*6.3 |

2*6.3 |

||

|

Hoisting power |

26 |

26 |

||

|

Total power |

42.6 |

42.6 |

||

|

Total Crane Weight |

t |

20.95 |

22.14 |

|

|

Max crane wheel load |

KN |

153 |

153 |

|

|

Protection class |

/ |

H |

H |

|

|

Insulation class |

/ |

IP54 |

IP54 |

|

|

Working temperature |

/ |

-20℃ ~ +50℃ |

-20℃ ~ +50℃ |

|

|

Steel |

/ |

Q235B |

Q235B |

|

|

Country of Origin |

/ |

China |

China |

|

Note: Recommended Crane Rail Specification (not included in quotation)

|

Type |

Top Width(mm) |

Bottom Width(mm) |

Height(mm) |

Weight(kg/m) |

|

P43 |

70 |

114 |

140 |

44.65 |

(The above picture is for reference to crane model only)

The double girder grab overhead crane fetching device is a grab bucket that can grab bulk materials. The double girder grab bridge crane has an opening and closing mechanism and a hoisting mechanism, and the grab is suspended on the opening and closing mechanism and the hoisting mechanism with four wire ropes respectively. The opening and closing mechanism drives the grab bucket to close and grab the material. When the bucket mouth is closed, the hoisting mechanism is started immediately, so that the four steel wire ropes are evenly loaded for hoisting work. When unloading, only the opening and closing mechanism is activated, and the bucket mouth is opened immediately to tilt the material. Except for the different lifting mechanism, the rest of the structure of the grab bridge crane is basically the same as that of the hook bridge crane.

Application of double girder grab bridge crane:

1. Double-girder grab bridge cranes are widely used in power plants, freight yards, workshops, docks, coal stations, etc. for the loading and unloading of bulk materials.

2. Double-girder grab cranes are strictly prohibited to be used in flammable and explosive environments. If there are special needs for use, non-standard design can be customized.

3. All mechanisms of the grab bridge crane are operated in the cab, and the directions for entering the platform door of the cab are: end entry, side entry and top entry.

4. The grapple crane is equipped with a grab bucket, and the style and model specification of the grab bucket can be selected according to the needs of use.

5. The opening direction of the grab is parallel and vertical. The grabbing device is a four-rope grab with double drums, which is simple in structure and reliable in operation. The grab can be opened and closed at any height. When the grabbing material particles are less than 100mm, the effect is good and the production efficiency is high. When the grabbed particles are 200mm large, a toothed grab is required.

Our products have passed CE (ECM) and ISO Certifications, and you can also specify a third-party agency for quality testing. Fees of third-party testing are not included in this offer.

Design and Construction Rules

All required standards for cranes are the FEM standard, DIN standard and Chinese National standard.

Europe Main National Standards

— 89/392/EEC standard (93/68/EEC)

— 91/368/EEC standard

— 73/23/CEE standard

— “EMC” standard 89/336/EEC

— EN 60204-1

— EN 292 mechanical safety

— ISO 2141

— ISO 2766

International Standards

— June 9, 1993 / Sept. 22, 1993 notice

— July 29, 1992, 92-765, 92-766, 92-767 notice

— DIN 5684

— DIN 15400; DIN 15401

— NFE 26-010

— NFE 26-030

Technical Standards

— FEM 9.511 Mechanical group

— FEM 9.661 Hoisting and traveling components size and quality standard

— FEM 9.671 Wire rope quality standard

— FEM 9.681 Travel motor choice

— FEM 9.682 Hoisting motor choice

— FEM 9.755 Electric hoisting equipment

— FEM 9.811 Electric crane standard

— FEM 9.901 Hoisting components design reference

— IEC 34-1 Traveling and allocation performance

— IEC 34-5 Protection grade standard

— IEC 947-5-1 Low voltage equipment

China Main National Standards

Design rules for cranes GB/T 3811-2008

Safety rules for lifting appliances GB 6067-2010

Common crane technical condition GB 7592-87

Crane-Overhead travelling crane and portal bridge crane

tolerances for manufacture and tracks laying GB/T 10183-2010

Crane-test code and procedures GB/T 5905-2011

General Bridge crane GB/T 14405-2011

Portal Crane GB/T 14406-2011

Crane & Lift Equipment Technical Performance and Acceptance Condition GB/T 17908-1999

Electrical installation and acceptation standard GBJ 232-82

Safety of Machinery – Electrical Equipment of Machines

Part 32: Requirements for hoisting machines GB 5226.2-2002

Electrical installation and acceptance standard GB 50256-96

[xyz-ihs snippet=”20-ton-Overhead-Crane-case-in-Pakistan”]Contact our crane specialists

Send us a message and we will get back to you as soon as possible.