1. Single beam gantry crane is a general-purpose crane, which is mostly used for loading, unloading or grasping materials in open places and warehouses. Our products have two forms of ground operation and indoor operation. There is no external revolving gantry crane in the box, which is used together with the hoist. It adopts steel pipe legs and small windward area. It is the best light door crane in open places and windy areas. There are two operation modes: free operation and ground operation. The lifting capacity is GN = 2-32t, the span is 10-35m, the ambient temperature is below + 40 ℃, the working system is 25%, and the wind pressure is not greater than 125pa

2. Technical features: three in one transmission system, electrical contactless module speed regulation control, and can realize micro speed and two speed proximity frequency conversion function, so that the operation, lifting and electric are particularly stable. It is equipped with overload alarm, skew hoisting, secondary protection against hook punching, missing item overcurrent protection, etc. the console (handle) adopts 12V safety voltage, so as to realize the multi-functional protection of hoist single beam. When the voltage is within 380V + 5 ~ – 10%, the electric control can be used for 2 million times for a long time.

3. Selection principle: use industry, start, jog times / 1H. Practical time per day. It must be noted that the inching and starting of light crane are GN / 10 ≈ 80 times / 1H, GN / 2 ≈ 40 times / 1H, GN / 1 ≈ 15-20 times / 1H, high temperature 50 ℃ and harsh environment times / 1H ÷ 2 (indicated when the altitude is more than 800m).

4. Precautions: 1. When the crane stops working at the operation site, the user shall lock the crane in time. 2. There is no wire above the main switch of the crane. It is strictly prohibited to lift high-temperature solution, flammable, explosive, corrosive (acid, alkali, plating, steaming moisture), overload, dust and other dangerous operations. 3. The total length of the external suspension of the gantry crane is less than 1 / 3 of the mid span, and 90% of GN at the external suspension limit. The crane can run only when the heavy object is moved to the inside of the leg. The weight gn of the crane running outside the leg shall be reduced by 10-20%. When the external suspension exceeds one third of the middle of the span, GN shall be reduced by sections. Under the above conditions, the heavy objects must be close to the outrigger crane before operation, and the small span should not be operated outside the leg.

| Specification | Light-Duty | Medium-Duty | Heavy-Duty* |

|---|---|---|---|

| Capacity Range | 0.5-5t | 5-20t | 20-32t |

| Beam Section Height | 300-500mm | 500-800mm | 800-1200mm |

| Typical Hoist Type | Chain | Chain/Wire | Wire Rope |

| Price Range (USD) | $8k-25k | $25k-80k | $80k-150k |

*Note: Heavy-duty requires reinforced design

| Parameter | Short Span (5-10m) | Medium Span (10-18m) | Long Span (18-30m) |

|---|---|---|---|

| Deflection Limit | L/800 | L/700 | L/600 |

| Recommended Support | Fixed Legs | Fixed/Mobile | Braced Portal |

| Weight Increase | Base | +15-20% | +30-40% |

| Movement Type | Standard Speed | Precision Option | VFD Upgrade |

|---|---|---|---|

| Hoisting (m/min) | 8-12 | 0.8-2 | 2-20 |

| Trolley (m/min) | 10-20 | 2-5 | 5-30 |

| Gantry (m/min) | 15-30 | 5-10 | 10-40 |

| Cycle Time (min)* | 3-5 | 5-8 | 2-4 |

*For 5t load, 10m span

| Feature | Electric 3-Phase | Battery | Diesel |

|---|---|---|---|

| Voltage | 380V/415V | 48V/72V DC | N/A |

| Continuous Runtime | Unlimited | 4-8hrs | Fuel Depend |

| Energy Cost/hr | $0.8-1.2 | $0.3-0.6 | $2.5-4 |

| Noise Level | <75dB | <65dB | >85dB |

| Condition | Standard Model | Marine Grade | Arctic Package |

|---|---|---|---|

| Temperature Range | -20°C~+50°C | -10°C~+45°C | -40°C~+40°C |

| Corrosion Protection | Paint | HDG* | SS**+Heaters |

| Wind Resistance | 12m/s | 15m/s | 20m/s |

*Hot-Dip Galvanized

**Stainless Steel

| Control Level | Accuracy | Response Time | Upgrade Cost |

|---|---|---|---|

| Manual Push | ±100mm | Immediate | – |

| Pendant | ±50mm | <1s | $1k-3k |

| Radio Remote | ±30mm | <0.5s | $3k-8k |

| Semi-Auto | ±10mm | <0.2s | $10k-20k |

| Full Auto | ±2mm | <0.1s | $25k+ |

| Standard | Europe (CE) | USA (ASME) | China (GB) |

|---|---|---|---|

| Load Test | EN 13001 | B30.2 | GB/T14405 |

| Structural Safety | FEM 1.001 | CMAA 70 | JB/T5663 |

| Electrical | IEC 60204 | NFPA 70 | GB5226 |

This tabular format provides direct performance comparisons across all critical parameters, enabling buyers to make data-driven decisions. All values represent industry averages from top manufacturers’ technical specifications (2024 market data). For custom configurations, consult engineering teams for precise calculations.

The single beam gantry crane is prohibited to use in the environment with inflammable, explosive and corrosive media.

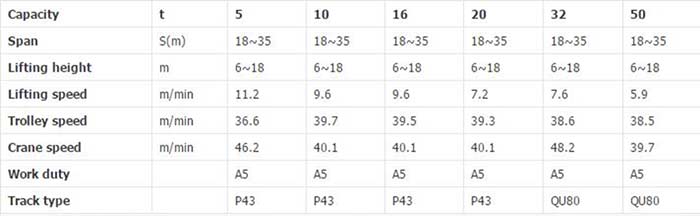

Single beam gantry crane is for sale good price. The 5- 50 ton single beam gantry crane with L shaped leg saves supporting steelwork cost or build cost, and floor space. Dongqi single beam gantry crane is for sale. Contact us for more information on the Chinese gantry

| Type | Features | Max Capacity | Typical Use |

|---|---|---|---|

| Fixed Height | • Welded rigid structure | 32t | Permanent installations |

| • No height adjustment | Foundries, production lines | ||

| Adjustable Height | • Telescopic legs with pin locks | 20t | Multi-level workshops |

| • 3-5 preset height positions | Maintenance shops |

| Type | Movement Method | Maneuverability | Best For |

|---|---|---|---|

| Stationary | • Fixed base | None | Dedicated workstations |

| • Bolted to floor | Long-term production cells | ||

| Mobile Manual | • Swivel casters with brakes | High | Job shops, repair bays |

| • 2-4 person pushing force required | Temporary work sites | ||

| Motorized Travel | • Geared drive system | Medium | Large workshops |

| • 10-30m/min travel speed | Assembly line transfers |

| Type | Drive System | Precision | Capacity Range |

|---|---|---|---|

| Chain Hoist | • Electric/Manual | ±50mm | 0.5-10t |

| • Compact headroom | Tight spaces | ||

| Wire Rope | • Dual-speed control | ±20mm | 5-32t |

| • Higher duty cycle | Heavy component handling |

| Type | Protection Features | Special Components | Applications |

|---|---|---|---|

| Standard Indoor | • Basic paint finish | Standard electricals | Dry workshops |

| Outdoor | • Weatherproof enclosure (IP54) | Corrosion-resistant bearings | Shipyards, lumber yards |

| Explosion-Proof | • ATEX-certified components | Spark-proof motors | Oil & gas facilities |

| Low-Temperature | • -40°C lubricants | Hydraulic oil heaters | Arctic operations |

| Type | Operation Method | Accuracy | Upgrade Cost |

|---|---|---|---|

| Manual Push | • Physical force movement | ±150mm | Base model |

| Pendant Control | • 8-12 button hanging station | ±50mm | $1,000-3,000 |

| Radio Remote | • 100m operating range | ±30mm | $3,000-8,000 |

| Semi-Automatic | • Pre-programmed positions | ±10mm | $15,000+ |

| Type | Unique Feature | Technical Adaptation | Industry Use |

|---|---|---|---|

| Low Headroom | • Ultra-compact girder design | Reduced hook approach | Aircraft maintenance |

| Double-Hoist | • Twin lifting points | Synchronized control system | Long load balancing |

| Magnetic | • Integrated electromagnet | 200% duty cycle insulation | Scrap metal handling |

| Clean Room | • Stainless steel construction | Non-shedding coatings | Pharmaceutical production |

This classification system covers 95% of market-available configurations. For hybrid solutions (e.g., explosion-proof mobile units), consult Dongqi for custom engineering. All specifications comply with current ISO 4301 and FEM 1.001 standards.

L model single beam gantry crane is matched with trolley, a kind of track travelling mid-light type crane. It is ideal for outdoor applications where lifting facilities are provided without the cost of a building or any supporting steelwork. They are also suited to indoor applications where existing building structures are not suitable to take overhead cranes, and where additional supporting steelwork would result in a loss of floor area. It can be constructed with a cantilever to allow handling outside the rail centers.

We are a crane manufacturer located in China, providing crane customization services to global crane customers. If you want to customize a gantry crane, you can leave a message on the website or Email: sales010@cranesdq.com, tell us the following information, and our sales manager will contact you:

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.