Dongqi Crane Machinery is professional logistics handling products exporter, with long history trading time having rich technical experience. We are located in Changyuan— the crane’s hometown, have passed the ISO9001 quality system certification, ISO14001 environmental management system certification and OHSAS18001 occupational health and safety management system certification of enterprise, and CE certification. our products are recommend by WTO. Dongqi always adhere to customers first,holding positive attitude to satisfy the customers’ the demand.

Good quality, high production effeciency, few maintance;

High loading strength, high working class;

Flexible operation, safe and reliable.

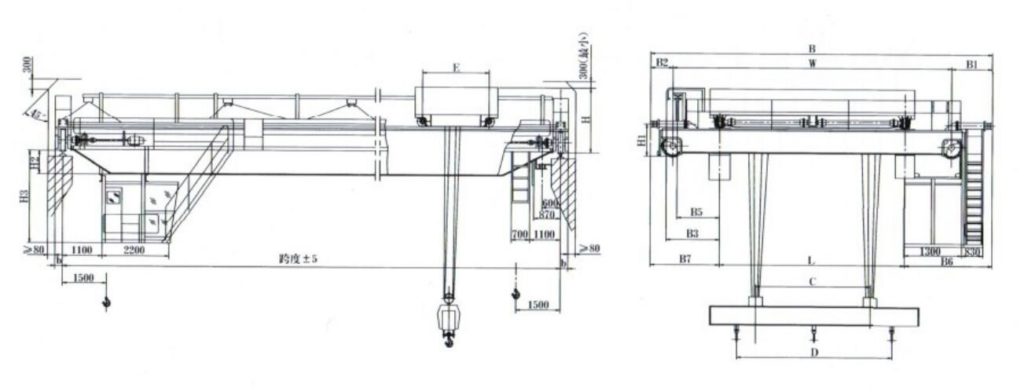

There are two carrier-beam:

one is vertical to main girder, one is parallel to main girder.

You can choose you need.

(1) In General

(2) Main Body

(3) Crane and Trolley

(4) Electric System

(5) Protection Devices

(6) Operation Device

QG Overhead Crane with Carrier-beam PDF

| Overhead Crane | Span(m) | Lifting Height(m) | Power Supply(V) | Price(USD) |

| 1 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $4000-60000 |

| 2 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $4500-62000 |

| 3 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5000-66000 |

| 5 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $5800-72000 |

| 10 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $6500-79000 |

| 16 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $7800-86000 |

| 20 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $8600-95000 |

| 25 ton | 7.5~31.5 | 6~30 | 220-480/3/50 | $9800-110000 |

The price of the above bridge cranes will change with the market, without further notice, for reference only. If you need an accurate price in the near future, please contact us.

Henan Dongqi Machinery Co., Ltd. is a domestic European standard crane manufacturer with intellectual property that focuses on independent research and development, and learns from foreign technology and experience as a supplement. In recent years, the company has continuously introduced processing equipment, and at the same time has carried out school-enterprise cooperation with Southwest Jiaotong University, Shanghai Jiaotong University and other institutions. Inheriting the concept of energy saving and consumption reduction, light weight, compact structure, small footprint, high working performance, maintenance-free, low noise and people-oriented concept of European cranes, new European standard products have been introduced.

The company covers an area of 240,000 square meters, with a total investment of 240 million yuan. The registered capital is 123 million yuan. There are more than 600 employees, including more than 150 management technicians and more than 20 engineers. There are 500 (sets) of various production equipment and testing equipment, and the annual comprehensive production capacity of cranes reaches more than 10,000 sets (sets). The company has carried out technical cooperation with many European machinery manufacturers, such as British SZW Company, German NORD Company, German SIEMENS Company, French Schneider Electric Company and many other companies. famous brand.

In recent years, the company’s products have been successively sold by Shanghai Electric Group, China Railway Intermodal Transportation, China Railway Corporation, China Railway Vehicles, China Railway No. 1 Bureau, China Railway Seventh Bureau, China Railway Tunnel Bureau, and PetroChina Technology Development Corporation (the company is mainly responsible for all overseas investments of CNPC). projects) and other large central and state-owned enterprises, and has received many orders. Our company is a domestic private enterprise that has entered Shanghai Electric Group with European standard cranes after crane manufacturers such as Konecranes, Demag, and Frantech. Industry blank large orders. Products are widely used in steel, electric power, petrochemical, machinery manufacturing, military industry, warehousing and logistics, papermaking and many other fields.

The company’s main products include: various European standard bridge cranes, gantry cranes, explosion-proof, metallurgical, European standard electric hoists, track laying machines, all-intelligent truss-type industrial robots, etc. Some key core parts are original products of British SZW company. Structural parts are produced in strict accordance with European process standards, and the performance of the whole machine reaches a high level.

Green and intelligent is our goal, we will provide you with reasonable design solutions, and tailor-made high-standard European standard cranes for you with technical and economic indicators.

Since its establishment, the company has been adhering to the business philosophy of “pragmatic, efficient, excellent, and strong”, striving for survival by quality and development by technology, strictly implementing the standards promulgated by the state, and has successively passed ISO9001 international quality system certification, ISO14004 environmental management system Certification, OHSAS18001 occupational health management system certification, has comprehensively improved the overall management level of the enterprise. In 2012, a management company was hired with a high salary to provide on-site guidance, from basic skills such as welding and assembly to advanced crane technology, employee quality and management methods and processes to carry out unified and meticulous training, so that the institutionalized and systematic program model was deeply rooted in the hearts of the people. The development of the team has laid a solid foundation. Dongqi company will surely go to glory on the road of crane industry.

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.