The shipbuilding gantry crane is a special lifting equipment that works on the dock, slipway or platform of the shipyard to carry out the lifting and turning over of the hull sections.

With the development of large-scale shipbuilding industry, the sales of shipyard gantry cranes and the demand for shipyard gantry cranes are growing rapidly. Compared with traditional gantry cranes, large shipyard gantry cranes have obvious advantages in the installation and transportation of hull sections.

It spans the dock (berth) and can provide on-site assembly services on the dock coverage surface. It not only has the functions of lifting and horizontal transportation, but also can realize the aerial flipping of the hull and adjust the sections to the necessary position for ship welding.

Shipbuilding gantry crane 200 ton is a kind of lifting equipment with large span, large lifting capacity, multifunction and high efficiency, specialized in section transport, docking and turnover of hull in shipyard or slipway.

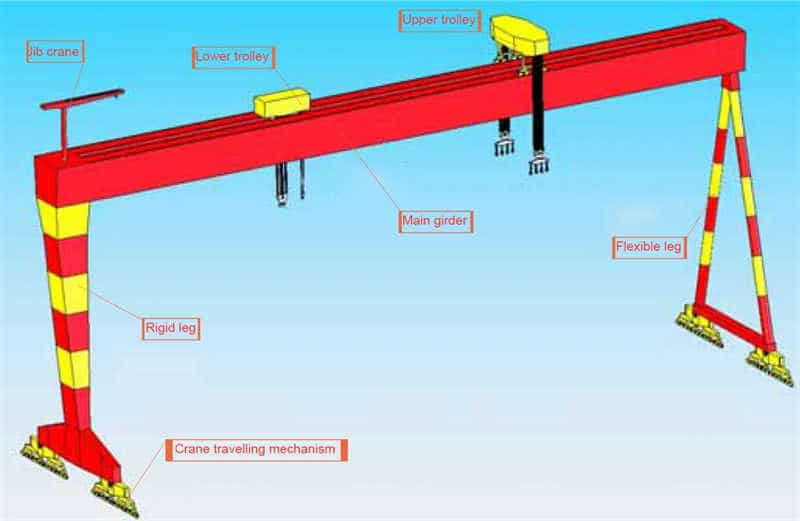

Shipbuilding gantry crane 200 ton mainly consists of main girder, rigid leg, flexible leg, upper and lower trolley, maintenance jib crane, crane travelling mechanism and electrical control.

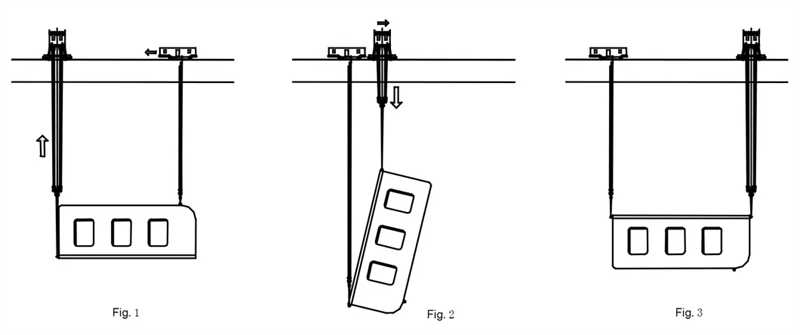

Shipbuilding gantry crane 200 ton achieves the turnover of hull through the cooperation of two trolleys. First, upper trolley bear the whole weight of hull through the adjustment of the position of hook(Fig.1), and lower trolley pass under the upper trolley. The hook is retied to another side of hull(Fig.2). Second, upper one will give up the hook, and Upper and lower one go on reverse running and then finish the turnover of hull(Fig.3).

| Item | Unit | 150t-82m | 200t-94m | 320-122m | 800t-160m | ||

| Rated lifting capacity | t | 150 | 200 | 320 | 800 | ||

| Span | m | 82 | 94 | 122 | 160 | ||

| Axle Base | m | 20 | 24 | 30 | 35 | ||

| Upper Trolley | capacity | t | 2×75 | 2×100 | 2×160 | 2×440 | |

| hoisting speed | m/min | 0.2~5~8~10 | 0.2~5~10 | 0.15~6 | 0~8~20 | ||

| traversing speed | m/min | 1~25 | 0.6~20~30 | 0.3~30 | 0~40 | ||

| Lower Trolley | capacity | t | Main120/Aux20 | Main150/Aux30 | Main200/Aux20 | Main450/Aux30 | |

| hoisting speed | m/min | main0.2~5~8~10/ aux18 | main0.2~5~10/ aux0.2~10 | main0.15~6/ aux0.2~20 | main0~8~20/ aux16~32 | ||

| traversing speed | m/min | 1~25 | 0.6~20~30 | 0.3~30 | 0~40 | ||

| Lifting Height | Upper Trolley | m | above rail top58/ below rail top12.5 | above rail top60/ below rail top6 | above rail top75/ below rail top9 | above rail top73 below rail top16 | |

| Lower Trolley Main | m | above rail top75 below rail top13.3 | |||||

| Lower Trolley Auxiliary | m | above rail top76 below rail top 13.3 | |||||

| Traveling speed | m/min | 1~30 | 0.6~30 | 0.4~30 | 0~45 | ||

| Wheel load | KN | ≤420 | ≤520 | ≤750 | ≤750 | ||

| Weight | t | 1066 | 1520 | 2980 | 4000 | ||

| Total power | KW | 650 | 790 | 1110 | 3500 | ||

| Power supply | \ | AC10kV 50Hz | AC10kV 50Hz | AC6kV 50Hz | AC10kV50Hz | ||

Contact our crane specialists

Send us a message and we will get back to you as soon as possible.